What is CNC cutting machine?

A CNC cutting machine, also known as a Computer Numerical Control cutting machine, is a mechatronics cutting tool. It drives the movement of machine tools through digital programs, and as the machine tool moves, the cutting tool attached to it cuts the object. This machine is mainly used for cutting steel plates and features integration, intelligence, graphical interface, and networking capabilities.

The history of CNC machines dates back to the 1940s, initially proposed by John T. Parsons of Parsons Corporation. He needed to manufacture complex helicopter blades and realized that connecting machines to computers was the future of manufacturing. CNC technology was originally a development of numerical control (NC) and gradually evolved into modern CNC machines. CNC machines are used in almost all industries for parts manufacturing, including various hard materials such as plastic, metal, aluminum, and wood. CNC stands for Computer Numerical Control, which relies on digital instructions, usually generated by Computer-Aided Manufacturing (CAM) or Computer-Aided Design (CAD) software. These software programs write G-code, which the controller on the CNC machine can read. The computer program on the controller interprets the design and moves the cutting tool and the workpiece to cut the desired shape from the workpiece. This automated cutting process is faster and more accurate than traditional manual tool and workpiece movement.

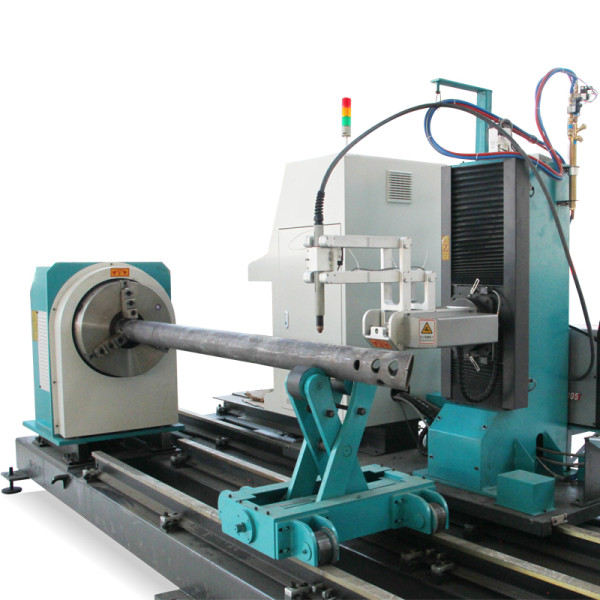

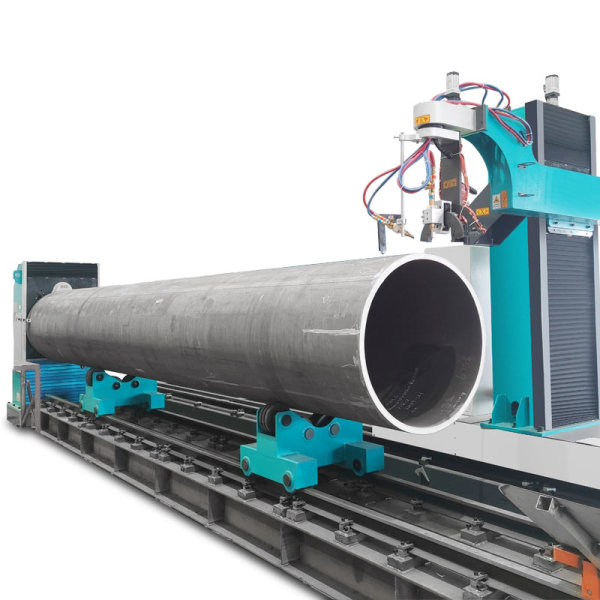

CNC Round Pipe Plasma Intersection Cutting Machine is special CNC equipment which is used for cutting metal pipe automatically.

Gantry CNC plasma and flame cutting machine is a kind of high-efficiency steel plate automatic cutting equipment.

H-Beam Cutting Robort has been widely used in steel structure prefabricated buildings.

CNC pipe plasma cutting machine is a kind of equipment that automatically calculates and cuts the joints of steel pipe ends.