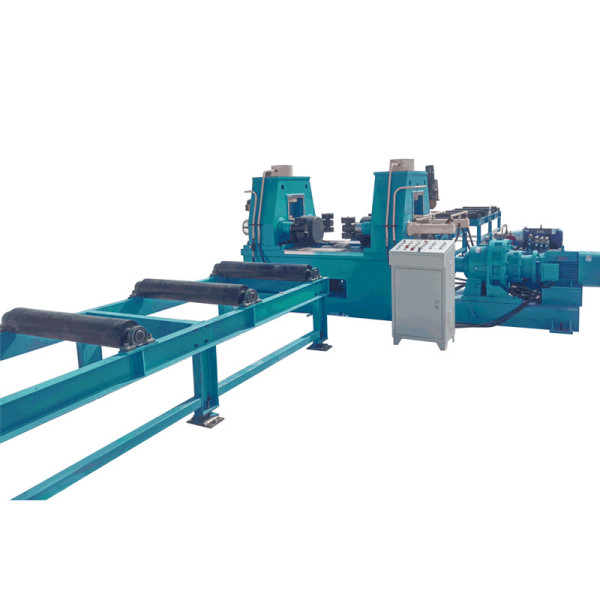

Standard H Heam Production Line

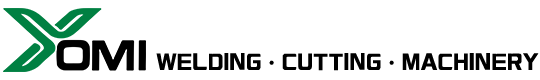

CNC plasma/ flame cutting machine

Heavy duty machine structure

a. High strength sheet after welded, aging treated

b. Intermittent welding for box structure, welding stress thus minimized

c. High rigidity and precision, light and small inertness

d. Operation panel installed, easy to operate

e. Shot-blasting and distressing treatment for structure surface

f. Self-guiding mechanism by spring rather than eccentric clamping structure, stable and smooth

g. Running without tight or loose clamping

1. Technical parameters

● Width of the flange: 200-600mm

● Thickness of the flange: 6-40mm

● Height of the web: 200-1500mm

● Thickness of the web: 6-32mm

● Length of the h beam: 4000-12000mm

● Assembling speed: 600-2000mm/min

2. Performance

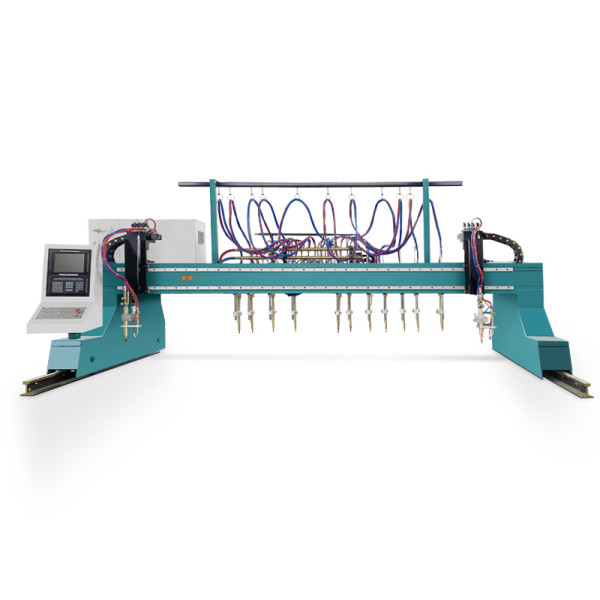

HG-1500 H beam automatic assembling machine is a specially designed for spot assembling H beam. During the assembling of the H beam, manual wheel will positioning the web in advance then hydraulic clamp is used for synchronized clamping and automatic centering it to ensure in the middle of the flange.

3. Supply range

● Machine body: main framework, upper pinch device, clamping aligning unit, driving reducer, motor, motor seat.

● Input conveyor: total 3 sets, pulling rod, pulling bar, protective cap.

● Output conveyor: total 3 sets, protective cap.

● Hydraulic system: oil pump station, high pressure hose, hydraulic cylinders, pipeline etc.

● Welder system: 2 sets of KR-350 Co2 welder and welding guns, wire feeder, pneumatic device.

● Spare parts: buttons*3pcs, 4A and 2A fuses*2pcs.

4. Technical documents

● Using manual

● Shipping list

● Certification of the machine

● Foundation

1. Technical parameters

● Width of the flange: 200-600mm

● Thickness of the flange: 6-40mm

● Height of the web: 200-1500mm

● Thickness of the web: 6-32mm

● Length of the h beam: 4000-12000mm

● Welding speed: 240-1500mm/min

● Welding position: ship-type welding seam

● Size of the usable welding wire: 3.2-5mm

2. Performance

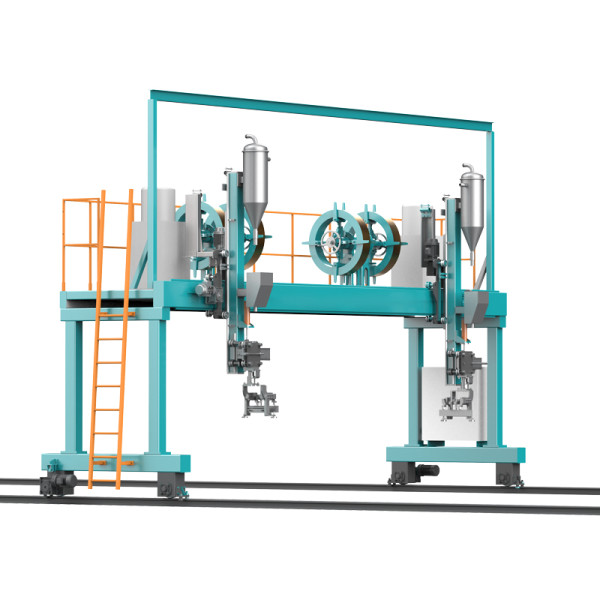

MZG1000*2 Gantry type submerged arc welding machine is specially designed for the welding of H beam. It realized the combination of welding control and trolley control and can be operated easily. Driven by alternating current converter, stable speed, digital display of the linearity speed, good reliability, floating type tracing to guarantee that the welding torch targeting at the welding seam accurately. The power line for the submerged arc welding can move on the portal frame to shorten the length of the control cable and the welding cable as far as possible to quicken the response, reduce the pressure and stabilize the welding current.

3. Supply range

● Main framework: gantry framework, travel unit, slider shelf, tube and accessories, flux machine seat, arc-guide device.

● Welding arm: 2 sets of welding arm, elevating unit, arm travel unit, guide plate and accessories.

● Flux recovery system: 2 sets of flux recovery unit, flux separating barrel, flux hopper, flux recovery and tube.

● Welder system: 2 sets of Huayuan MZ-1000 submerged arc welder, wire feeder, controller, connect wire.

● Accessories: rails, power line, welding cable.

● Spare parts: welding nozzle*6pcs, bottoms*2pcs, 6A fuse*2pcs.

4. Technical documents

● Using manual

● Shipping list

● Certification of the machine

● Foundation

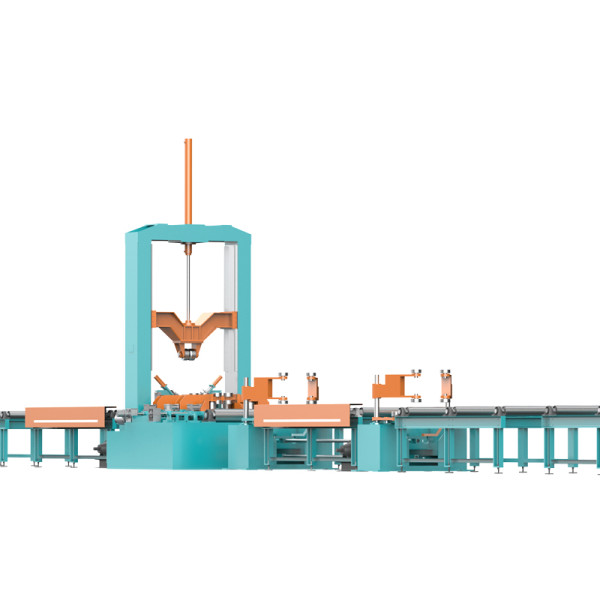

1. Introduction

There will be certain degree of deformation on flange of H-beam after welding. This machine is mainly for straightening this kind of deformation. It features in simple operation, high straightening speed, good straightening quality. It can be widely used in many fields such as metallurgy structure, metallic structure, and industry installation.

2. Technical parameters

● Width of the flange: 200-600mm

● Thickness of the flange: 6-40mm

● Minimum height of the web: 200mm (when web has a height within 200-350mm and flange has a thickness of less than 16mm, use straightening sub-roller)

● Main motor: 11KW

● Press motor: 1.5KW * 2

● Straightening speed: 12000mm/min

3. Supply range

● Main framework: base, left-and-right framework, motor, reducer, press roller, main driven roller, straightening sub-roller.

● Conveyor: base framework, roller, bearing, bearing seat, adjust block (including input conveyor × 2 sets, output conveyor × 2 sets).

● Electric control: electric control box, wire.

● Spare parts: switch*2pcs, wrench*1pc.

4. Performance

HYJ-40 H beam mechanical straightening machine is specially designed for the straightening of the flange. The main machine uses 11KW electric motor and pin gear reducer drive characterized by high efficient and high speed. All the straightening rollers are made of high-quality alloy steel. Besides, the machine is put under advanced hot treatment to prevent crackles. All the parts are reinforced to stabilize the correction and realize the long service life.

5. Technical documents

● Using manual

● Shipping list

● Certification of the machine

● Foundation