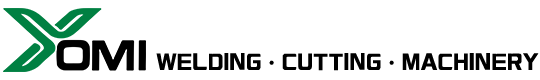

H Beam assembly welding straightening machine

H Beam assembly welding straightening machine

The PHJ series is a special welding H-beam equipment developed for the production of steel structures. The machine has the advantages of one machine and three uses, high efficiency, low energy consumption and small footprint.

The whole machine is optimized and integrated design, automatic centering and positioning, realizing high efficiency, mass automatic processing.

Automatically align the center assembly and correct the welding at the same time.

Compared with the ordinary H-beam production line, this machine saves the plant area and the number of operators required is also greatly reduced.

H Beam Assembly Machine is suitable for H -shaped steel with symmetrical and equivalent sections.

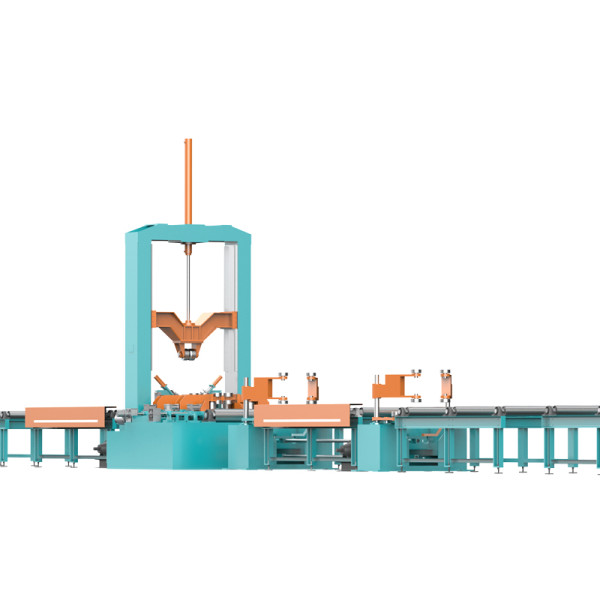

H beam gantry saw welding machine is special equipment used for H-beam welding.

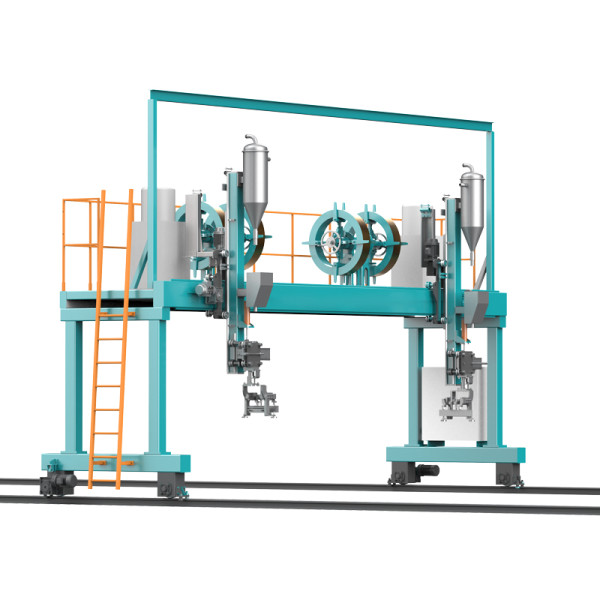

H beam hydraulic straightening machine is specially used to straighten the deformation of flange after welding.

The T / H beam assembly welding straightening machine developed by our factory is designed on the basis of absorbing the advantages of similar foreign products and combining the actual situation of domestic steel structure production. Its main structural advantages are: the all-in-one welding and straightening machine is a special equipment for assembly, welding, and straightening T / H steel beam. It will integrate the three equipment of assembly machine, gantry welding, and straightening machine into one equipment. To carry out, significantly improve production efficiency, reduce equipment costs, save equipment installation space, is the production equipment for efficient production of H-Beam and T-Beam. In addition, this equipment uses CNC programming control to automatically complete the automatic feeding, automatic centering, automatic welding, automatic straightening and other work in the production process of T / H steel beam welding, which saves a lot of manpower and provides automatic production of the entire profile solid foundation.

Name | Parameters |

Flange width | 200-800 mm |

Web height | 200-1500 mm |

Web thickness | 5-25mm |

Flange thickness | 5-25mm |

Workpiece length | 6000-15000mm |

Processing speed | 300—1000mm/min |

Fast return speed | 3m/min |

Welding position | 45 degree welding torch |

Welding wire size | ¢3—¢5mm |

Wire feeding speed | 30—120m/min |

Drive mode and power | Frequency conversion speed motor |

flux recycling machine | 50kg×2 |

Weight of welding wire bracket | 250Kg |