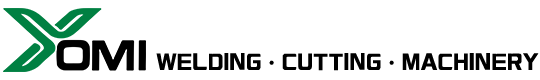

Assembly Welding And Straightening Integrated Machine

Assembly Welding And Straightening Integrated Machine

1.It is a special machine for assembling, welding and straightening of H beam/I beam/T beam.

2.It integrates the processes of assembly machine, gantry welding and straightening machine into one machine.

3.It significantly improves production efficiency ,reduces labour cost, saves installation space.

Advantages Compared with Traditional Beam Production Line

Labor Saving:Traditional beam production line requires 5 workers, our 3 in 1 beam production line only needs 2 workers.- assembly, welding and straightening at the same time.

Footprint Saving: The total length of traditional beam production line is about 90m, while 3 in 1 beam production line is about 30m lo, which saves two-thirds of loor area.- It can welding two seams once, while traditional only can welding one seam once.

High Efficiency: Traditional beam production line needs to flip four times, 3 in 1 beam production line only needs to flip one time and the deformation is small.Saving 2/3 of the workspace.

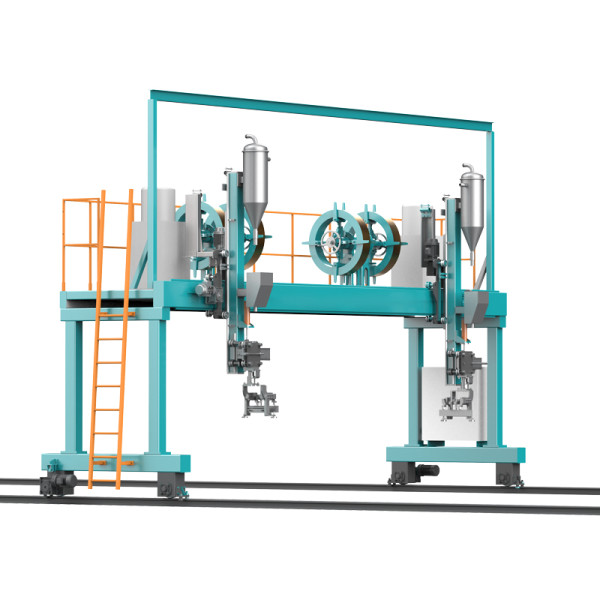

H Beam Assembly Machine is suitable for H -shaped steel with symmetrical and equivalent sections.

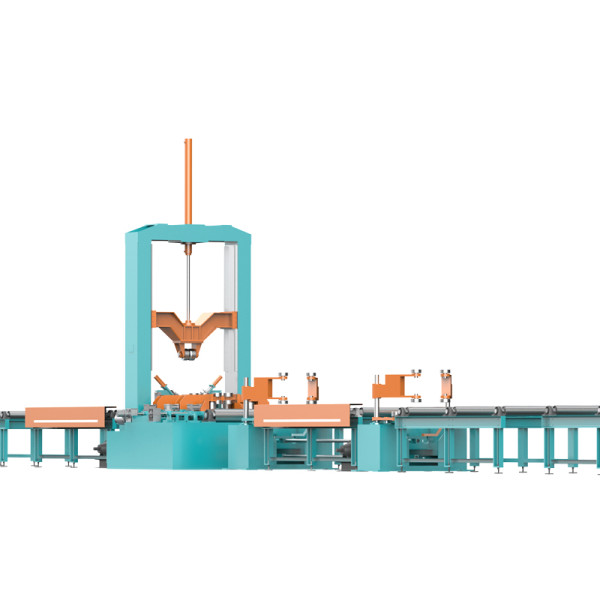

H beam gantry saw welding machine is special equipment used for H-beam welding.

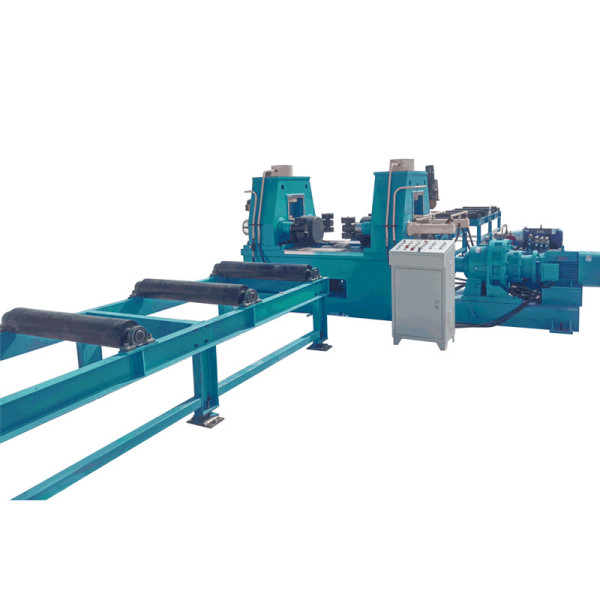

H beam hydraulic straightening machine is specially used to straighten the deformation of flange after welding.