What equipment does steel structure factory need?

Steel structure factory typically need a variety of equipment to carry out their operations efficiently. Some common equipment includes:

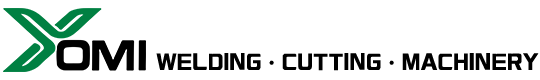

1、Steel cutting machines: such as plasma cutters, laser cutters, or water jet cutters to cut steel beams and plates accurately.

H beam Fiber Laser Cutting Machine Suitable for H-beam steel, U-beam steel, I-beam steel, slot steel and other profiles.

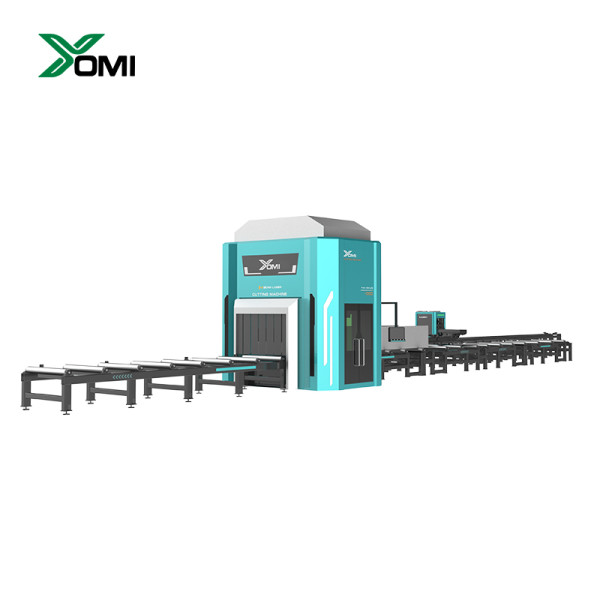

H-Beam Cutting Robort has been widely used in steel structure prefabricated buildings.

H Beam CNC Plasma Cutting Machine is mainly used for cutting of steel structure enterprises

2.Welding machines: such as MIG welders, TIG welders, or stick welders to join steel components together.

3.Overhead cranes: to lift and move heavy steel beams and structures within the facility.

4.Bending machines: such as press brakes or roll benders to bend steel plates and beams into desired shapes.

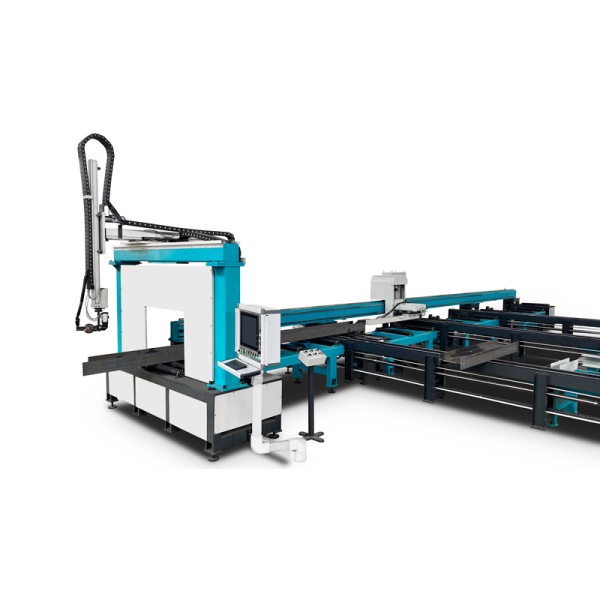

5.CNC machines: for precision drilling, milling, and other machining processes on steel components.

6.Surface treatment equipment: such as shot blasting machines or painting booths to prepare and finish steel structures.

7.Safety equipment: such as welding helmets, safety goggles, gloves, and protective clothing to ensure the safety of workers.

These are just a few examples of the equipment that a steel structure factory may need to have in their facility to carry out their operations effectively.

Machine tool equipment Accuracy Plasma H Beam Automatic Cutting Drilling Beveling Machine.

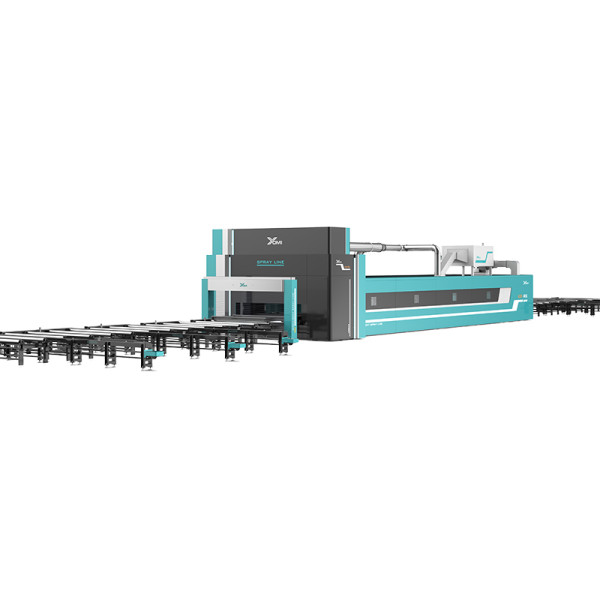

H Beam Spraying&Painting Production Line 3D scanning can complete components of various sizes and shapes.

Intelligent Automatic Spraying&Painting Machine Production Line for Steel structure factory.