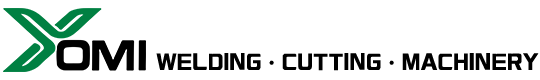

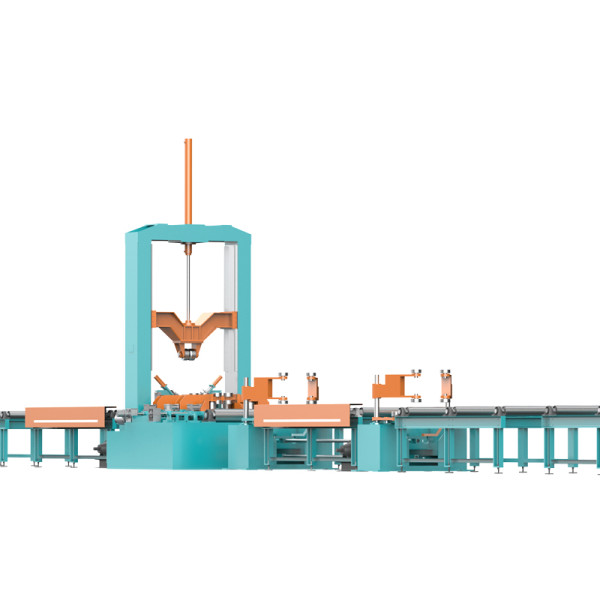

what is Box Beam Assembly Machine?

The Box Beam Assembly Machine typically automates the process of assembling the individual components that make up a box beam. This may include tasks such as:

Positioning and aligning the components: The machine precisely positions and aligns the various parts that need to be assembled, such as the flanges, webs, and gussets.

Joining the components: The machine then joins the components using welding, bolting, or other methods. For welding, the machine may include a welding unit that can automatically apply the weld beads to connect the parts.

Checking the assembly: After the components are joined, the machine may perform quality checks to ensure that the box beam is assembled correctly and meets the required specifications.

Output and handling: Finally, the machine outputs the assembled box beam and prepares it for further processing or shipment. This may include tasks such as painting, labeling, and stacking.

By automating the box beam assembly process, these machines can significantly increase production efficiency, reduce labor costs, and improve product quality.