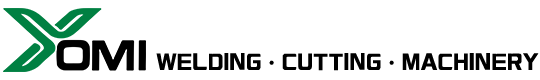

H Beam Assembly Machine

| Categories | H Beam Assembly Machine |

|---|---|

| Brand | YOMI CNC Cutting&Welding Machinery |

| Model | YM-PHJ-0818,YM-PHJ-0820 |

| Web height | 200~1800mm |

| Web thickness | 6-40mm |

| Flange width | 200~1000mm |

| Flange thickness | 6-40mm |

| Work-piece length | 4000~15000mm or as user’s request |

| Welding process | Single arc single wire,Double arc double wire |

| Assembly speed | 0.5~6mmin |

| Update Time | Apr 3,2025 |

Detail Information

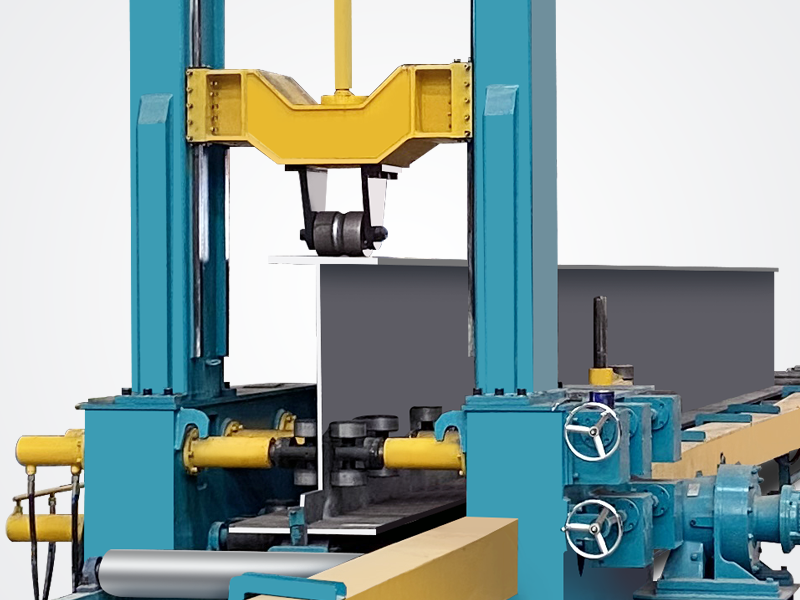

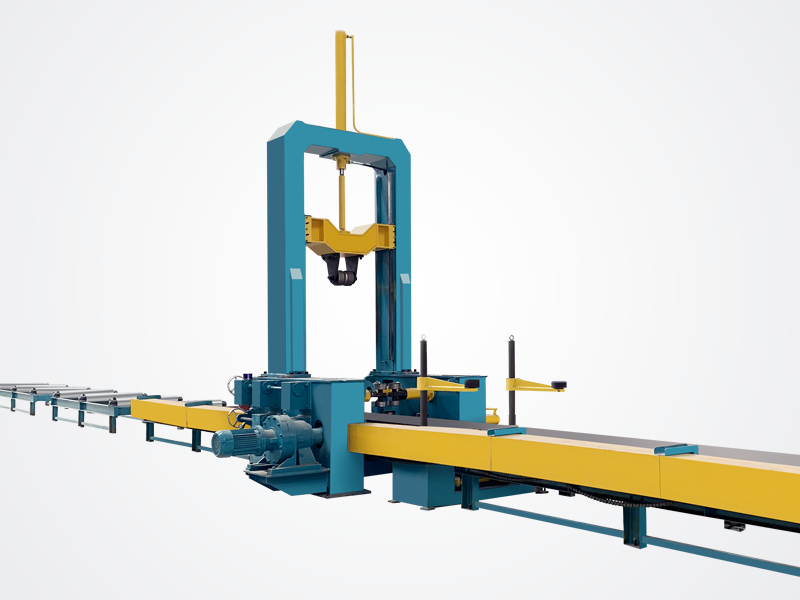

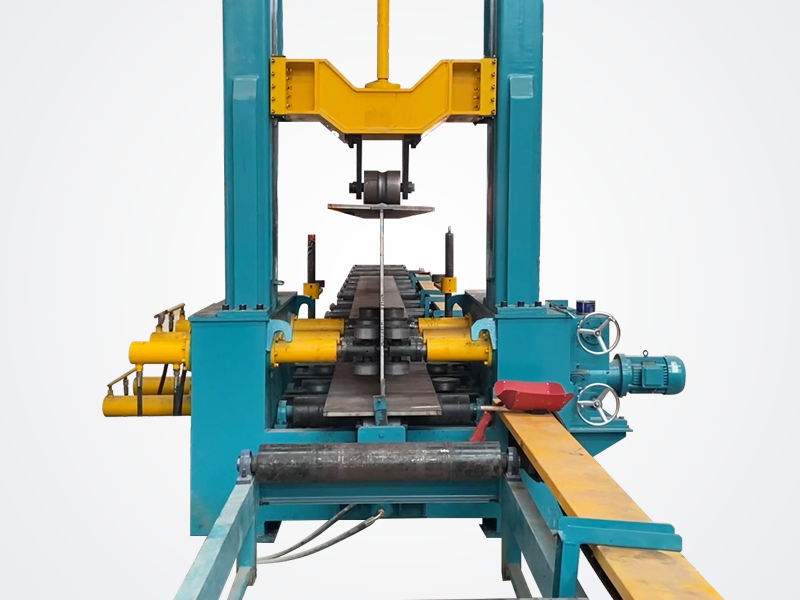

H/T Beam Assembly Machine

1.It is suitable for assembling symmetrical H beam,I beam,T beam with constant cross section.

2.The flanges and web are centered by three sets of centering manipulator groups at input roller table, then sent to the host,

3.The hydraulic cylinder drives synchronous clamping and centering device on both sides to realize self-realization.

4.PLC controls spot welding and fast forward speed, weld length and interval length during entire assembly process, which is easy to operate and it has high assembly efficiency.

Technical Parameters

|

Model

|

YM-PHJ-0818 |

YM-PHJ-0820 |

|

Web height

|

200-1800mm

|

200-2000mm

|

|

Web thickness

|

6-32mm

|

6-60mm

|

|

Flange width

|

200-800mm

|

200-1000mm

|

Flange thickness | 6-40mm | 6-80mm |

Workpiece length | 500-6500mm/min | 4000-15000mm/min |

Power | 8.4kw(excluding two welding machines) | 12.7kw(It does not include welding power source) |

Details Introduction

Service Life

Main Drive Wheel

Large Webs

Welding Torch Holder

Centralized Lubrication System

Product Advantages

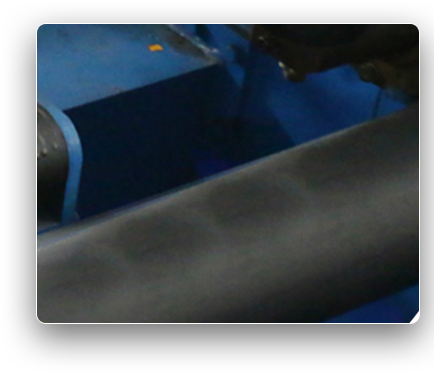

Precise positioning

The workpiece is clamped by the flange & the web hydraulic cylinder and the screw to ensure the correct positioning of the workpiece.

Safe and stable

The upper hydraulic cylinder drives the pressure roller to press the workpiece tightly, so that the web and the flange are closely attached, and the welding torch is sent to the mechanism, driven by the oil cylinder to the welding position.

Wide range of applications

Widely used in many fields such as steel structure processing etc.

High productivity

Flanges and webs are clamped and centered tightly, accurate positioning and high production efficiency.

Customer Case

Review

- Loading...

Related Products

Please send your message to us

More than a manufacturer and distributor, we focus on your business, One-stop Solution For All Your Piping Needs.

- Name

- Tel

- *Title

- *Content

Contact Person

- Name:

- Ellian WhatsAPP

- Tel:

0086-13153107480

- Email:

- sales@yomi-china.com

- WhatsApp:

- https://wa.me/8613153107480

- Address:

- Factory Adress: 9 Changjie Road, Ningjin,Dezhou, P.R.China